STEEL SHOT AMMUNITIONNS: FABARM LEADING THE WAY!

EXCLUSIVE: STEEL SHOT AMMUNITIONS “HIGH PERFORMANCES” CAN BE USED IN INNER HP™ AND EXIS HP™CHOKE TUBES MORE CLOSED THAN MODIFIED ( *** ½ ) , EVEN IN THE LONG 0,7 AND XTREME 0,9 CHOKE TUBES! NO OTHER COMPETITOR CAN OFFER THE SAME BENEFITS!

All the weapons manufacturers today, like FABARM yesterday, authorize the use of steel shot ammunitions from the choke CYLINDER to MODIFIED only. For all the other they mention « do not use for steel shot » engraved on the choke tubes. This restriction is based on the CIP regulation, which mention, to shoot steel shot ammunitions, a maximum angle of 1 degree for the choke conic profile.

|

|

|||

| Traditional choke tube | INNER HP™(HYPERBOLIC PROFILE) |

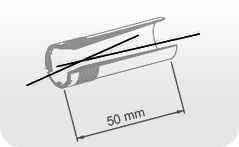

On this choke tube drawing (50 mm long, other chokes can be 65 mm long with a similar section ) the choke is made with 40 mm conical and 10 mm cylinder to stabilize the pellets before the barrel exit. In case of a MODIFIED (½ - *** ) choke tube ( reduced diameter of 0,5 mm compared to the bore ), the conical section will have approximately a angle of 1 degree. That’s why the CIP regulation establish the MODIFIED choke tube as a LIMIT for steel shot use.

FABARM is today the only trademark which gives the possibility to hunters and shooters to use STEEL SHOT AMMUNITIONS “high performances” in choke tubes improved modified (INNER HP or EXIS HP LONG 0,7) and full (INNER HP or EXIS HP XTREME 0,9).

HOW IT’S POSSIBLE?

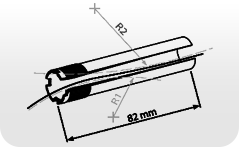

1- BY INCREASING THE CHOKE TUBES LENGTH:

• INNER HP™ 12 Ga: 82 mm (3,23 “)

• INNER HP™ 20 Ga: 82 mm (3,23”)

• EXIS HP™ 12 Ga: 92 mm (3,62”)

2- BY REPLACING THE CURRENT STRAIGHT CONICAL SECTION BY A HYPERBOLIC CURVED CONICAL SECTION (No edge, less friction and more progressiveness).

|

|

|||

| EXIS HP™ | INNER HP™ |

THE RESULTS:

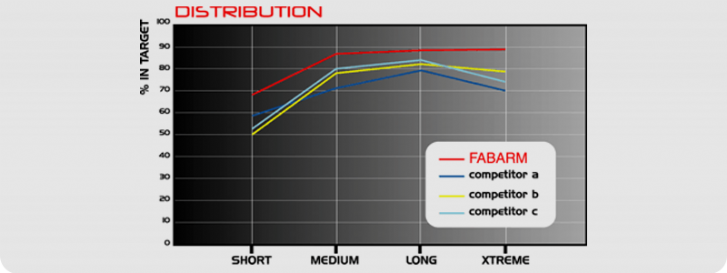

Distance : 30 meters ( 98 feets ) - Target : Ø 75 cm ( 29,5 inches ) - Ammunition : 12 Ga, 35 grams, steel shot N°4 ( 220 pellets )

COMMENTS:

A

The possibility to use chokes tubes higher than MODIFIED is a very large benefit. Concretely when competitor barrels with MODIFIED choke tubes have a distribution of 76 % in the target, the TRIBORE HP with XTREME 0,9 choke tube has a distribution of 89 % in the target!

With FABARM XTREME 0,9 choke tube, there are 40 POINTS OF IMPACTS MORE in the target! = + 15 % points of impacts

B

These results are obtained not only because of the revolutionary choke tubes, but also because of the TRIBORE® barrel ( Patented ).

The TRIBORE barrel is the only one without the disadvantage of all over-bored barrels ; a very poor penetration ! The over-bored barrels are looking for a better distribution. The innovation was to increase the bore diameter to reduce the friction and by consequence the deformed pellets number. It was born for shooting disciplines ( sporting and trap ) where penetration was not the objective ...the goal was a better distribution to break more clays.

Of course with traditionnal over-bored barrels, there is a lack of penetration: The gas is compressed in a higher volume (the bore diameter is increased from 18,40 to 18,85 mm), so less pression , a lower pellets speed ..and by consequence a REDUCED PENETRATION ( Ec= ½ mv2 ).

SO WHAT ABOUT TRIBORE BARREL?

The TRIBORE barrel developped 10 years ago by FABARM ( the TRIBORE HP barrel introduced in 2005 is an improved version of TRIBORE ), in reaction to over-bored barrels which were successful in Sporting and trap , is the concrete application of the VENTURI principe which said that reducing the diameter of a tube with fluid in movement inside ( gas, water etc... ) automatically the speed of this fluid will be increased.

Example : we wash our car with water, we press the tube between thumb and index finger... The pression of the water increases itself!

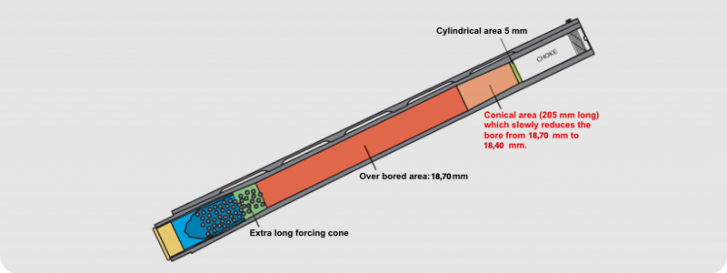

It’s the same logic with the TRIBORE barrel. The long conical section ( 205 mm – 8,07 “ ) which slowly reduces the bore from 18,70 to 18,40 mm will automatically increase the pellets speed, and so by consequence the penetration. No other barrel has the same performance!

SO, IN THREE WORDS TRIBORE HP BARREL IS:

1. An over-bored area to reduce frictions and recoil (diameter 18,70 mm).

2. A long conical area (205 mm) which reduce the bore diameter and which increase the pellets speed.

3. New and revolutionary choke tubes with HYPERBOLIC PROFILE.

C

Deep drilling technology:

This stress is so high that few competitors are frozen cryogenically their tubes to reduce a little the tension…but the results are more marketing than concrete…

This stress is so high that few competitors are frozen cryogenically their tubes to reduce a little the tension…but the results are more marketing than concrete…

There is a perfect solution to produce the best tubes: to drill solid bars of chrome molybdene steel.

Because this technology is expensive , our two largest competitors are using it only on their high grade custom shop shotguns.

To give better barrels to our clients FABARM uses only the deep drilling technology to produce all the tubes of all our shotguns